Double Girder Electromagnetic Overhead crane

Double girder electromagnetic overhead crane is a crane that uses magnet to carry steel products. Turn on the current, absorb the magnet steel items, and transport them to the designated location. When the current is cut off, the magne force disappears and the steel product falls. Magnetc cranes are very convenient to use, but must be used with electric current. It can be used in metallurgical plants or steel plants.

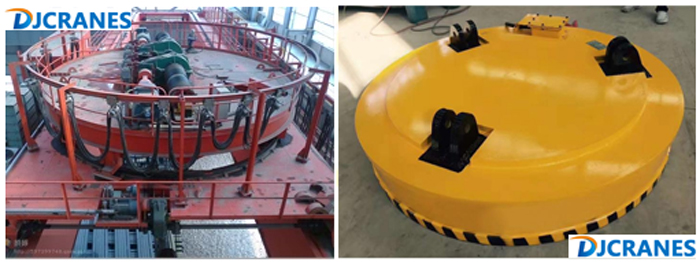

Double girder electromagnetic overhead crane with magnet is composed of beams, walking mechanism, lifting trolley, electrical parts and magnet spreaders. After the power is off, the magnet suction of the bridge crane can last for a minimum of 20 minutes. If you have requirements for the magnet retention time of the electromagnet, you can tell us in advance.

The shape of the magnet spreader can be customized according to the size of the material to be lifted, such as round, square, and rectangular. There are two types of magnet double girder overhead cranes: magnet chuck and magnet beam. Magnet beams can also be divided into two types: non-rotating beams (vertical or parallel to the main beam) and rotating beams (upper beam or suspended beam).

Double girder electromagnetic overhead crane can generate strong magnetic field force. Steel billets, steel coils, steel bars, scrap iron and various other iron materials weighing tens of tons are very convenient for handling and storage. It not only saves labor, but also improves work efficiency. When the crane is working, as long as the current in the solenoid coil keeps on, the lifted heavy objects will not fall. If the power is cut off for some reason, the magnet suction can last for at least 20 minutes. If the temperature of the iron material you hoist is high, please explain to us in advance the temperature of the iron material that the magnet needs to hoist.

Specifications of double girder overhead electromagnetic crane:

Lifting Capacity | t | 15 | 20 | 32 | 40 | ....... |

Span | m | 22.5--31.5 | ||||

Lifting height | m | 6~18 | ||||

Lifting speed | m/min | 15.8 | 15.8 | 15.1 | 15.1 | ....... |

Cross Travelingspeed | m/min | 103 | 103 | 104 | 113 | ....... |

Crane Traveling speed | m/min | 42.8 | 42.8 | 43.3 | 43.3 | ....... |

Working class | A6-A7 | |||||

The Feature Of Crane

Feature:

1, for lifting 5t~50t materials;

With exquisite box welded main beam. Computer optimized main beam design, good performance and light weight;

3. Compact structure, light weight, high lifting height;

4. The maximum span is 32 meters;

5. Widely used in workshops, metallurgy, warehouses, assembly workshops, etc.

Mechanism:

1.Box shape

2.High quality carbon steel Q235B and Q345B;

3.The girder is connected by high-strength screws;

4.The welding seam is tested by X-ray and ultrasonic;

5.Forged wheels;

6.Compact structure, small size and light weight;

7.The lifting mechanism is an open winch.

8. Compact geared motor drive, stepless control, hardened gear and safety disc brake;

9.Good running performance, stepless speed regulation, stable operation;

10.. After the main beam is welded, perform sandblasting sa2.5 to relieve internal stress;

11. Spray high-quality epoxy zinc-rich primer with an oil film thickness of 140μm;

Electrical System:

1.Power supply through stepless slide line;

2. The lifting mechanism and the walking mechanism are independent of each other and can walk at the same time;

3.Reasonable installation of components, convenient inspection and maintenance;

4.The cable is suspended in a cable rack fixed in the cable rack, which slides on the galvanized C-shaped steel;

Safety protection device:

Overload limiter, limit switch (lifting and driving), interlock protection device, buffer, busbar protection board, anti-collision device, main disconnect switch, emergency stop system and motor overload protection.

How to select the suitable Electromagnet crane

1) lifting Capacity. It is the maximum weight of the lifting goods.

2)Lifting height: The lifting height of the goods expeact the height of the electromagnet .

3)The size of the lifting goods, such as length,wide , height , diameter or others.

4)Do you need trolley rotation or electromagnet rotation?

5)The temperature of the lifting goods. If the temperature of the lifting goods is not the ambient temperature, In order to send the crane fully meet your use, please share the maximun temperature of the lifting goods.

If you want to konw more information or any question about double girder electromagnetic overhead crane , contact us.

- The last one:What are the main aspects of crane lightweight?

- The next one:Five Factors that Affect Gantry Crane Design

info@dejunindustry.com

info@dejunindustry.com +86 13721448067

+86 13721448067