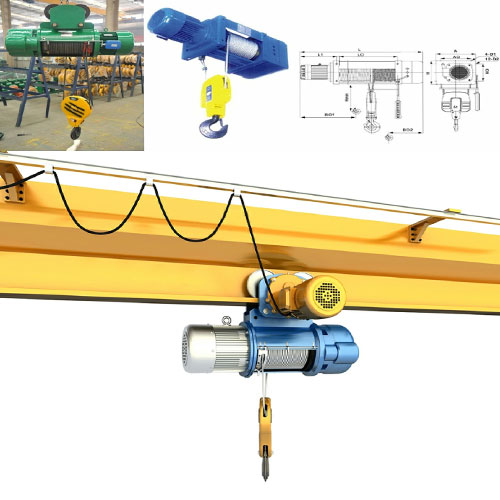

Wire Rope Hoist

As an efficient and reliable lifting device, the wire rope hoist is widely used in industry, construction, ports and logistics. Knowing wire rope hoist is an indispensable step to select one suitalbe for factory.

What is a wire rope hoist?

A wire rope hoist is a type of lifting equipment that uses steel wire ropes as the load-bearing components and belongs to light and small lifting machinery. It is mainly composed of steel wire ropes, drums, electric motors/manual mechanisms, accelerators, hooks, control systems, etc.

The wire rope hoist is usually divided into electric wire rope hoist and manual chain block according to driving mode.

Electric wire rope hoists are usually driven by motors, which are highly efficient and suitable for frequent operations. They can be divided into fixed types (installed on I-beam tracks) and trolley types (with a electric trolley). They are commonly used in factories, ports, workshops, and other places.

Manual chain blocks are usually operated by pulling the hand chain with human power and do not require electricity. They are mainly used for operations without power supply or for temporary work, such as field construction, emergency repairs, etc.

Specification of wire rope hoist

Electric wire rope hoist specification | ||||

Type | CD/MD | HC/HM | BCD | HB |

Lifting capacity (t) | 0.5 - 16 | 16 -32 | 0.5 - 16 | 16 - 32 |

Lifting height (t) | 6 - 30 | 9 - 48 | 6 - 30 | 9 - 48 |

Lifting speed (m/min) | 8 (0.8/8), | 6 (0.6/6), 2.4 (0.24/2.4) | 8 (0.8/8), | 6 (0.6/6), |

Power supply | 380v 50 Hz | 380v 50 Hz | 380v 50 Hz | 380v 50 Hz |

Explosion-proof | ExdIIBT4 | ExdIIBT4, ExdIICT4 | ||

Available for being customized according to your actual needs | ||||

Manual chain block specification | |

Lifting capacity (t) | 0.5 - 100 |

Lifting height (m) | 0.5 - 3.5 |

Ambient Temperature | -20℃ to 40℃ |

Available for being customized according to your actual needs | |

Besides, you can see more details of how to maintain electric wire rope hoists here.

What are the advantages of wire rope hoists?

Advantages of electric wire rope hoists

1. High load carrying capacity and large lifting heights

One of the significant advantages of electric wire rope hoists over other small lifting equipment is their wide load range, which makes them suitable for all stages of lifting, from light to heavy duty, and for a wide variety of industrial scenarios. It also has the advantage of a large lifting height and customizable rope lengths, making it suitable for high-rise buildings, large workshops or deep wells.

2. Smooth operation and precise control of electric wire rope hoists

Electric wire rope hoist with low runout and anti-sway, good wire rope flexibility, with frequency conversion drive can realize smooth take-off and landing, reduce load shaking. At the same time, it is suitable for precision assembly with accurate positioning. Multi-speed adjustment can be adapted to different working conditions.

3. High durability and low maintenance of electric wire hoists

Long wear-resistant life of electric wire rope hoist: wire rope surface is galvanized or plastic coated, corrosion-resistant and high temperature-resistant (-40℃~200℃), longer life than chain. With modularized design, key components (motor, reducer, rope sheave) can be quickly replaced and maintenance is convenient. Meanwhile, it is equipped with self-lubrication system, and some high-end models are equipped with automatic lubrication device, which reduces the frequency of manual maintenance.

4. Safety and reliability of electric wire rope hoists

Electric wire rope hoist with multiple braking protection, standard electromagnetic brake + mechanical brake, automatic locking in case of power failure to prevent falling. It also has overload protection with integrated sensors and automatic shutdown in case of overload. Anti-slotting of wire rope, rope guide plus rope pressure device to ensure that the wire rope is neatly arranged to avoid accidents.

5. Adaptation to complex environments

Explosion-proof wire rope hoists are suitable for chemical industry, oil fields and other flammable and explosive places. Corrosion-resistant design, stainless steel wire rope or special coating can cope with humid, acid and alkaline environment. High/low temperature adaptation, special wire rope can work in extreme cold or high temperature environment.

Advantages of manual chain blocks

1. No electricity required, highly adaptable

Powerless dependency: Can be used in situations where there is no power supply (such as construction sites, farmlands, and remote areas) even during power outages or in outdoor operations.

Safety and explosion-proof: Suitable for flammable and explosive areas (such as oil depots, chemical plants), without the worry of motor sparks causing danger.

2. Simple structure, high reliability

Mechanical transmission: Pure mechanical structure, low failure rate, simple maintenance.

Resistant to harsh environments: More adaptable to high temperatures, humidity, dust, etc. (The motor and circuit of the electric wire rope hoist are susceptible to environmental influences.)

3. Flexible operation, precise control

Easy fine-tuning: Manual operation enables precise control of the lifting position, suitable for scenarios requiring fine adjustments (such as equipment installation and hole alignment).

Speed control: The speed of the manual pulling is determined by the user, avoiding the shock caused by sudden start and stop of the electric hoist.

4. Low cost, practical and economical

Low price: The purchase cost is much lower than that of electric wire rope hoists, making it suitable for scenarios with limited budgets.

Low maintenance costs: No need to replace the motor or electronic components. Daily maintenance only requires lubrication and inspection of the steel wire rope.

5. Lightweight and easy to install

Small in size and light in weight: convenient to carry and suitable for temporary installation (such as for mobile use in vehicles).

No need for complex supports: It can be directly fixed onto simple supporting structures such as beams or tripod stands.

6. Safety Redundancy

Dual braking system: Most manual hoists are equipped with mechanical load brakes + hand chain brakes. Even if the handle is released, it can automatically lock to prevent heavy objects from falling.

No risk of out-of-control: If the circuit or brake of the electric hoist malfunctions, it may accidentally fall. The manual hoist is fully controlled by human power and is therefore more reliable.

Conclusion

Besides wire rope hoists, Henan Dejun Industry Co., Ltd also provides electric chain hoists. You can see more details of differences between wire rope hoists and chain hoists here.

- The last one:6 differences between PA mini electric hoist and electric wire rope hoist

- The next one:What is Advantage of Eot Crane?

info@dejunindustry.com

info@dejunindustry.com +86 13721448067

+86 13721448067