What are the advantages of fixed column cantilever crane and its installation steps?

Fixed column jib crane, also known as: column jib crane, column cantilever crane, is a new generation of light lifting equipment manufactured to adapt to modern production. Because of its unique performance advantages, it is recognized and welcomed by people, so what are the advantages of fixed column crane equipment? Below, Henan Dejun Crane will give you a detailed introduction!

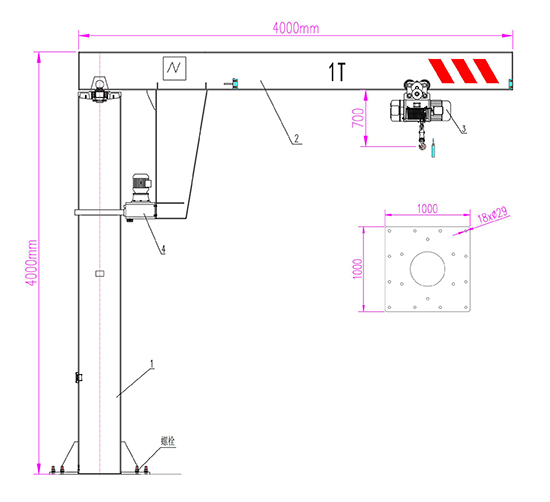

Components of fixed column cantilever crane equipment

The fixed column cantilever crane is composed of column equipment, reversing equipment, jib equipment and electric hoist, etc., mainly including upper column, lower column, main beam, main beam pull rod, lifting mechanism (electric chain hoist), transfer organization, electrical system, ladders and maintenance channels. The lower end of the column is fixed on the concrete foundation, and the swing arm is reversed, which can be reversed according to users' needs. The reverse part is divided into manual reverse and electric reverse. The electric chain hoist is installed on the track of the swing arm and is used for lifting heavy objects.

What are the advantages of fixed column cantilever crane equipment?

Fixed-column cantilever cranes are suitable for short-distance, frequent use, and densely distributed lifting operations. They have the characteristics of high efficiency, energy saving, labor saving, small footprint, and easy operation and maintenance. The electric chain hoist has the functions of lifting and reciprocating operation on the beam. The cantilever beam can be driven by the reducer on the reversing device to reverse the rollers. The electrical control box is installed on the chain hoist.

First of all, the fixed column cantilever crane is specially made for modern production and manufacturing. It has high reliability and has great advantages in short-distance production. Even if people frequently operate it, it is not easy to damage it.

Secondly, the fixed-column cantilever crane brings great convenience to people, improves work efficiency, greatly reduces work pressure, and at the same time can play a role in energy saving and environmental protection.

The fixed-column cantilever crane is more flexible and convenient to use. Even if a fault occurs, it is easier for people to repair it, and because of its structural performance advantages, the equipment will not occupy too much land area.

How to install the jib crane?

Install the column: Insert the column into the inner ring of the base plate, weld the base plate and the column on both sides of the base plate, and then weld several reinforcement plates to the base plate and column to complete the installation of the cantilever column base plate.

Installation of the end plate and the waist ring track: the shaft of the column crane and the end plate are adjusted in place and then welded and fixed to ensure the verticality of the shaft. After connecting the wiring board, put it into the column, and weld and fix the column according to the size of the drawing. The waist ring rail is inserted into the column, and after adjusting the corresponding position according to the size of the drawing, it is welded and fixed with the column to complete the installation.

Installation of the slewing sleeve: According to the size of the drawing, the bearing seat and the slewing sleeve are fixed together by welding through the connecting plate, pressed into the spherical roller bearing, and then the left side of the slewing sleeve is sealed with the bearing pressure plate. The sealing plate connected by the sealing plate is welded on the right side of the rotating cylinder, and is connected by bolts. The sealing plate is removed during on-site installation, and the current collecting device is installed in the rotating sleeve. After the internal parts of the cantilever-type rotary sleeve are installed, install the sealing plate to complete the installation.

Bracket installation: weld the shaft on the motor mounting plate, install the main wheel and auxiliary wheel, and then weld and fix the square tube, trapezoidal plate, and steel plate according to the drawing size. Weld the bracket to the cantilever and complete the installation according to the drawing size.

On-site installation of the column cantilever crane: remove the round nut on the column, fix the cantilever on the column through the rotating shaft and the waist ring track, then install the round nut in the rotating device on the rotating shaft, and then install the current collector in sequence ring and locking urethane nut. The ring cable passes through the inside of the column, exits through the central hole of the rotating shaft, connects to the inside of the slip ring rotating device, and installs the slip ring bracket and carbon brush. The end of the carbon brush is connected to the cable and introduced from the middle of the rotating device. Go to the electric control cabinet, through the contactor switch in the electric control cabinet, connect the cable to the running motor of the rotating device and the lifting electric motor, and the installation is completed.

If you have any questions about the fixed column cantilever crane, please feel free to contact us.

- The last one:Container Gantry Crane

- The next one:Electric Double Girder Gantry Crane

info@dejunindustry.com

info@dejunindustry.com +86 13721448067

+86 13721448067